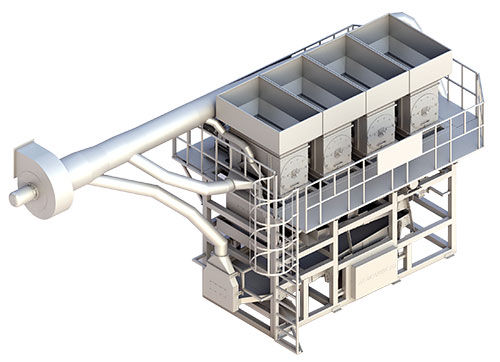

PEANUT SHELLER AKYUREK PS 4x3

The Akyurek Technology Peanut Sheller is designed to shell peanuts with high efficiency, high capacity and minimum split creation.

Each unit contains

Sheller Cylinders

Three screening boats

Hull aspiration

Vacuum Channels

Centrifugal Aspirator

Service Platform

Sheller cylinders

- Peanut Sheller is designed with ease of operation and low maintenance in mind.

- The shelling grates are easy to change, quick change feature allows the operator to easily vary shelling grates as the size of the peanuts change. under a load under a load of sheller cylinders due to directly driven of its motors and gear reducer.

-Directly driven by its motor and gear reducer, the shelling cylinder has the ability to start under a load.

Three Screening Boats

Balanced Eccentric System

- is fitted with counter weights ensuring steady runing

- involving minimum stress on building and steel structures

- is fitted with “heavy duty” bearings

- ensures maximum utilisation of the cleaning effect of the sieves owing to accurately attuned stroke and RPM.

Ball Box

- ensures efficient cleaning of sieves by means of rubber balls

- can maintain the cleaning effect at extremely low temperatures as the rubber balls are cast in a very suitable material

- is cast soild so that it prevents stuck seeds etc. (selfcleaning)

- is separately mounted in the scren shoes which ensures a quick change of sieves without removing the ball boxes

Hull aspiration Vacuum Channels

- eliminates light shells

- through which shells, dust etc. are led with the airflow to the after suction system.

Centrifugal Aspirator

- The impeller is self-cleaning and dynamically balanced. The spiral housing is made of welded steel plate.

- direct coupled flange motor

Servie Platform

- Easy access to Sheller and Aspiration for service and maintenance.

- Cat walk and safety bars.